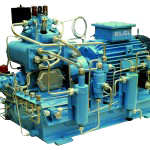

ELGi’s EN Series screw compressors provide a unique design feature, housing all functional components within a single unit, making them an ideal choice for industrial applications where size, efficiency, and cost are essential factors. These compressors offer a small footprint, high reliability, and low maintenance requirements, making them an attractive option for a variety of industries such as textiles, food processing, paper, automotive, small machining, and fabrication workshops.

The compressors boast an energy-efficient airend, resulting in lower running costs and a more compact design that reduces noise. The models come in both base/mounted variants and side-mounted drier options, with a range of power options, from 2.2kW to 5.5kW with a 220L receiver to 7.5kW to 15kW with a 270L receiver.

Additionally, the system parameters of these compressors are easily monitored through the user-friendly neuron controller, making maintenance and troubleshooting simple and easy.

ELGi’s EN Series screw compressors offer an efficient and reliable solution for various industrial applications that require compressed air.

Applications

- Textiles

- Food processing

- Paper

- Automotive

- Small machining and fabrication workshops

- Energy efficient airend

- Compact footprint and low running noise

- Reliable and low running cost

- Models available as base/mounted variants and also with side mounted drier

- 2.2kW to 5.5kW are available with 220L receiver and 7.5 to 15kW are available with 270L receiver

- Easy monitoring of system parameters with user friendly neuron controller