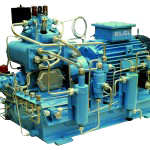

The piston air compressor, also known as a reciprocating air compressor, is a high-quality air compressor that uses pistons to compress the air. Due to their performance and durability, these compressors are used in a variety of industries.

Oil-Lubricated Compressors

WHAT IS A RECIPROCATING AIR COMPRESSOR?

A reciprocating air compressor uses a piston pushed by a crankshaft to deliver gases at excessive pressure. The procedure involves the piston moving downwards, lowering pressure within the cylinder, permitting the air to fill in. The piston then moves upwards, compressing the air and pushing it into the garage tank. This cycle repeats, ensuring a continuous supply of compressed air.

TYPES OF RECIPROCATING COMPRESSORS

Single-Acting Reciprocating Compressor: In this type, the piston compresses the air in one direction of its movement.

Double-Acting Reciprocating Compressor: Here, the piston compresses the air during both the upward and downward strokes, making it extra green.

Oil-Free Reciprocating Compressor: This kind of Piston air compressors uses substances that provide lubrication without the need for oil, ensuring cleaner air output.

Oil-Lubricated Reciprocating Compressor: These use oil for lubrication, which helps in reducing wear and tear and extends the compressor's lifespan.

WHAT ARE THE BENEFITS OF A RECIPROCATING AIR COMPRESSOR?

Piston air compressors provide numerous advantages, making them a popular choice in various applications :

Durability: They are designed for long-time use.

Efficiency: They can deliver high pressure air with noticeably low power consumption

Versatility: Suitable for a wide range of applications , from small to large industrial units.

Cost-Effective: The Piston air compressor lowers initial investment and maintenance costs compared to other types of compressors

How to Pick the Right Industrial Reciprocating Compressor for Your Needs:

Capacity (CFM - Cubic Feet per Minute) : Determine the volumetric flow rate of air required for your applications. This involves calculating the total air demand, including all tools and equipment that will be using compressed air. It's essential to ensure that the compressor can consistently deliver the required CFM without overloading.

Pressure Requirements (PSI - Pounds per Square Inch): Identify the operating pressure needed for your specific applications. Different tools and processes require different PSI levels. Ensure that the compressor can maintain the necessary pressure consistently, factoring in potential pressure drops across the system.

Duty Cycle: Evaluate the compressor's duty cycle, which is the ratio of run time to rest time. Industrial applications often demand a high-duty cycle, sometimes up to 100%. Ensure that the compressor is rated for continuous operation if your application requires it, to prevent overheating and undue wear.

Space and Installation Considerations: Assess the available space for installation and any specific requirements, such as ventilation, foundation, and access for maintenance. Compressors require adequate space for cooling and may need vibration isolation mounts to minimize noise and mechanical stress on the installation site.

Maintenance and Reliability: Consider the ease of maintenance and the availability of spare parts. Look for compressors with accessible components for routine maintenance tasks like oil changes, filter replacements, and valve adjustments. Check the reputation of the manufacturer and the availability of technical support and replacement parts in your region.

Additional Technical Factors:

Power Supply : Ensure compatibility with your facility's electrical infrastructure. Industrial compressors typically require three-phase power.

Cooling System : Reciprocating compressors generate significant heat. Choose between air-cooled or water-cooled systems based on your cooling requirements and available resources.

Lubrication : Decide between oil-lubricated and oil-free compressors based on the air quality requirements of your applications. Oil-free compressors are essential in industries where oil contamination is unacceptable.

Noise Levels : Consider the noise level of the compressor, especially if it will be located near workspaces. Look for models with noise-reducing features or plan for sound insulation measures.