Piston air compressors are versatile machines that play a crucial role in various industries and applications. Their ability to convert mechanical energy into compressed air has led to their widespread use, making them an integral part of many businesses.

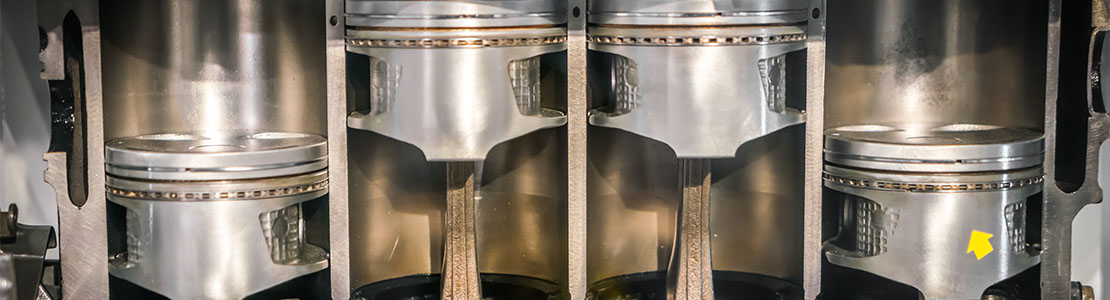

Piston air compressors, also known as reciprocating compressors, are mechanical devices that utilize pistons to compress air. These compressors operate on the principle of positive displacement, where air is drawn into a cylinder and compressed using the up-and-down motion of the piston. The compressed air is then stored in a tank and can be used for a multitude of applications.

Benefits of Piston Air Compressors

Piston air compressors offer several benefits that make them a popular choice for many industrial processes:

High-Pressure Capability

Piston compressors can deliver high-pressure air, making them ideal for applications requiring significant pressure, such as powering pneumatic equipment and machinery.

Durability and Longevity

These compressors are intended to last, with sturdy construction that can handle severe use and tough conditions. They can have an extended operational life if properly maintained.

Cost-Effective

Piston compressors are less expensive than other types of compressors. Their simple design and fewer moving components help to lower maintenance and repair expenses.

Wide Range of Sizes

Piston compressors are available in a range of sizes, from small portable devices to huge stationary systems, making them suitable for a wide range of applications.

Easy Maintenance

Piston compressors are easy to maintain as they have fewer intricate components. This lowers downtime and allows the compressor to operate for extended periods.

Reciprocating vs Rotary: Types of Piston Compressors

Piston air compressors come in two main types: reciprocating Compressors and rotary Screw air compressors. Let's delve into the differences:

Reciprocating Compressors: Operating like a car engine, these compressors use a piston within a cylinder to compress air. They are ideal for intermittent use and applications requiring high pressure.

Rotary Compressors: These compressors compress air using rotating mechanisms. They are quieter and better suited to continuous operation, making them ideal for industrial settings with high air demand.

Applications and Uses

The versatility of piston air compressors allows them to find application in numerous industries and settings:

Automotive Industry

In vehicle repair shops and production facilities, piston compressors are utilized for tasks such as tyre inflation, painting, and running pneumatic tools.

Construction Sector

Piston compressors power jackhammers, nail guns, and concrete vibrators on construction sites, increasing efficiency and production.

Food and Beverage Industry

In food processing, these compressors assist in packaging, labeling, and filling operations. They provide clean and oil-free air essential for maintaining product quality.

Medical Applications

Piston air compressors are essential in healthcare facilities, as they power breathing equipment and other medical devices that require a constant supply of compressed air.

Manufacturing Plants

Piston compressors help to keep various manufacturing processes running smoothly by powering conveyor systems and operating automated machinery.

Because of their efficiency, reliability, and versatility, piston air compressors have proven to be useful tools across sectors. These devices continue to play an important role in increasing productivity and meeting operational goals, whether it's inflating tyres, powering equipment, or enabling industrial operations.